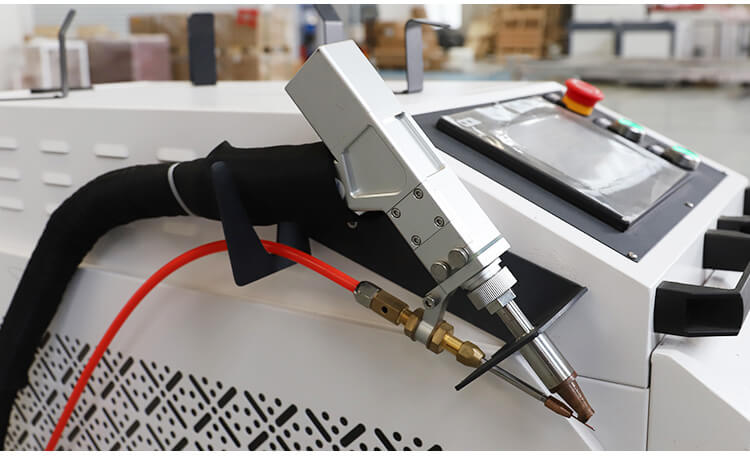

Handheld Fiber Laser Welding Machine 1000w 1500w 2000w

This handheld fiber laser welding machine is one of the most popular welding machines in the current world. It adopts a handheld welding head which is very convenient to operate. It has high welding efficiency and small thermal impact. This machine can weld various metals including thin metal plates.

Product Features:

High Power and Precision: The 1500W laser power provides ample energy for deep penetration welding, while the advanced laser technology ensures precise control and accuracy, resulting in strong and durable welds.

Portable and Compact Design: Designed with portability in mind, this machine is lightweight and compact, allowing for easy transportation and flexibility in various working environments. It can be used on-site or moved between different welding stations effortlessly.

User-Friendly Interface: The machine features a user-friendly interface with intuitive controls, making it easy to set welding parameters and monitor the welding process. Operators can quickly adapt to the machine and achieve consistent welding results.

Wide Welding Range: The 1500W Portable Laser Welding Machine offers a wide welding range, making it suitable for a variety of materials, including stainless steel, carbon steel, aluminum, copper, and more. It can handle thin sheets as well as thicker materials with ease.

Non-contact Welding: The laser welding process is non-contact, eliminating the need for physical contact between the welding tool and the workpiece. This reduces the risk of contamination and damage to the materials, resulting in cleaner and higher-quality welds.

High Efficiency and Productivity: The high power output and precise control of the laser beam allow for fast and efficient welding, increasing productivity and reducing production time. This machine is capable of high-speed welding while maintaining excellent weld quality.

Advantages:

Precise and Reliable Welds: The 1500W Portable Laser Welding Machine ensures precise control over the welding process, resulting in strong, reliable, and aesthetically pleasing welds. It minimizes the risk of defects, such as porosity and spatter, improving overall weld quality.

Versatile Applications: This machine can be used in various industries, including automotive, aerospace, electronics, medical, and more. It is suitable for welding components, joints, seams, and repairs, providing versatile solutions for different welding needs.

Cost-effective Operation: The laser welding process offers several cost-saving advantages. It requires minimal consumables, such as filler materials, and reduces the need for post-welding treatments or refinishing. It also reduces material waste and rework, contributing to cost efficiency.

Enhanced Safety Features: The 1500W Portable Laser Welding Machine is equipped with advanced safety features, such as protective enclosures and interlocks, ensuring operator safety during the welding process. This promotes a safe working environment and minimizes the risk of accidents.

Minimal Heat Affected Zone (HAZ): Laser welding produces a narrow and concentrated heat-affected zone, reducing the heat impact on the surrounding material. This minimizes distortion, warping, and material discoloration, particularly important for delicate or heat-sensitive applications.

Harness the Power of Portable Laser Welding:

With our 1500W Laser Welding Machine, you can achieve precise, efficient, and high-quality welds wherever you go. Experience the advantages of laser welding, streamline your welding operations, and take your welding capabilities to new heights.

Contact us today to learn more about how this advanced technology can benefit your welding applications and enhance your productivity.

Handheld Laser Welding Gun for Aluminum Other Metal

Laser welding machines typically use a high-power laser beam to melt and fuse the material being welded. The laser beam is precisely controlled using a computer, allowing for precise control of the welding parameters such as the laser power, welding speed, and beam shape.

Introduction to Laser Welding Machine

A laser welding machine is an advanced industrial equipment used for precision welding of various metal materials. It utilizes a high-intensity laser beam to melt and fuse the workpieces together, creating strong and durable welds. Laser welding machines offer numerous advantages over traditional welding methods, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding.

Key Features:

- Precision and Accuracy: Laser welding machines provide exceptional control over the welding process, allowing for precise positioning and accurate weld formation. This ensures consistent weld quality and minimizes the need for post-welding treatments.

- Speed and Efficiency: With high welding speeds and minimal heat-affected zones, laser welding machines can significantly improve production efficiency. The concentrated heat source allows for rapid and precise welding, reducing cycle times and increasing overall productivity.

- Versatility: Laser welding machines are capable of welding a wide range of metals, including stainless steel, aluminum, titanium, copper, and more. They can handle various material thicknesses and complex joint configurations, making them suitable for diverse industrial applications.

- Non-contact Welding: Laser welding is a non-contact process, which means there is no physical contact between the welding tool and the workpiece. This eliminates the risk of contamination or damage to the material, making it ideal for welding delicate or sensitive components.

- Enhanced Control and Automation: Laser welding machines can be integrated into automated systems, allowing for precise control and repeatability. They can be programmed to perform complex welding patterns, making them suitable for high-volume production lines.

- Reduced Distortion and Heat Input: Laser welding generates a concentrated and localized heat source, resulting in minimal distortion and reduced heat input into the workpiece. This is particularly beneficial for welding thin materials or components that are sensitive to heat.

Applications: Laser welding machines find applications in various industries, including automotive, aerospace, electronics, medical devices, jewelry manufacturing, and more. They are used for welding components such as sheet metal, tubes, wires, sensors, connectors, batteries, and intricate assemblies.

Conclusion: Laser welding machines offer unparalleled precision, efficiency, and versatility for metal joining applications. With their advanced features and capabilities, they have become an essential tool for modern manufacturing processes, ensuring high-quality welds and enhancing overall productivity.

Handheld Laser Welding Gun

Handheld laser welding is a type of laser welding that is performed using a portable, handheld laser welding device. This technique is particularly useful for welding hard-to-reach areas or for welding large, bulky components that are difficult to move.

Handheld laser welding devices typically use a fiber laser, which produces a high-power laser beam that can be delivered through a flexible fiber optic cable. This allows the operator to easily maneuver the laser beam to the desired location, even in difficult-to-reach areas.

One advantage of handheld laser welding is that it can be performed without the need for a dedicated welding table or fixture. This can save time and reduce setup costs, making the technique particularly useful for small-scale production runs or for repairs and maintenance work.

Another advantage of handheld laser welding is that it can produce high-quality welds with minimal distortion, due to the precise control of the laser beam. This can result in strong, reliable welds that are resistant to cracking and other defects.

However, handheld laser welding can also be more challenging than traditional laser welding techniques, as it requires a high degree of skill and precision on the part of the operator. Care must be taken to ensure that the laser beam is delivered to the correct location, and that the welding parameters are properly controlled.

Overall, handheld laser welding can be a highly effective technique for welding a wide range of materials, including aluminum, steel, and other metals. By using a high-quality handheld laser welding device and following best practices for laser welding, itis possible to achieve excellent results and create strong, reliable welds for a variety of applications.

Laser Welding Aluminum

Laser welding is a popular technique for joining aluminum, due to its ability to produce high-quality welds with minimal distortion. However, welding aluminum with a laser can be challenging, as the material has unique properties that can make it difficult to weld.

To ensure successful laser welding of aluminum, there are several techniques that can be employed. One key technique is to use a high-power laser, as this can help to ensure that the weld has sufficient penetration depth and a narrow heat-affected zone.

Another important technique is to use a suitable shielding gas, such as argon or helium, to protect the weld from atmospheric contamination. This can help to prevent the formation of porosity in the weld, which can weaken its strength.

It’s also important to carefully control the laser welding parameters, such as the laser power, beam diameter, and welding speed. These parameters can be adjusted to optimize the weld quality and prevent defects such as cracking or distortion.

In addition to these techniques, it’s important to use high-quality aluminum alloys and to properly prepare the welding surfaces. This can help to ensure that the weld has good mechanical properties and is resistant to corrosion.

Overall, laser welding of aluminum can be a highly effective technique for producing high-quality, strong welds. By using the right techniques and materials, it’s possible to achieve excellent results and create welds that meet the highest standards.

igoldencnc laser 28 w

https://www.igoldenlaser.com/laser-welding-machine/