High Speed Steel Cutting Tools Industry

Summary:

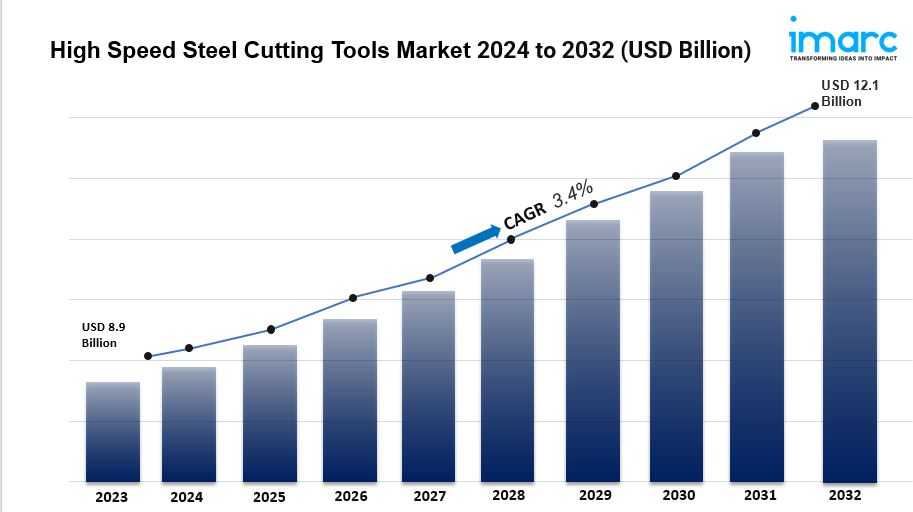

- The global high speed steel cutting tools market size reached US$ 8.9 Billion in 2023.

- The market is expected to reach US$ 12.1 Billion by 2032, exhibiting a growth rate (CAGR) of 3.4% during 2024-2032.

- Based on the region, the market is classified into North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa.

- By the type, the market is segmented into milling, drilling, tapping, reaming and counterboring, broaching, and others.

- Based on the technology, the market is divided into conventional and CNC (computerized numerical

- control).

- On the basis of the end use industry, the market is categorized into automotive, aerospace and defense, oil and gas, energy and power, marine, and others.

- The growth of industries like construction and heavy machinery manufacturing is increasing the demand for these tools.

- Government investments in infrastructure and manufacturing sectors, particularly in developing economies, are also contributing to the market's expansion.

Industry Trends and Drivers:

Rising Demand for Precision Engineering in Automotive and Aerospace

The need for precision engineering is becoming increasingly important in the automotive and aerospace industries, driving demand for high-speed steel (HSS) cutting tools. These industries require tools capable of delivering high accuracy and maintaining tight tolerances to ensure the production of critical components such as engine parts, gears, and turbine blades. HSS cutting tools are preferred due to their ability to perform well in high-temperature environments while maintaining their cutting edges. The automotive industry, focusing on fuel efficiency and lightweight materials, requires tools that can handle new, harder metals, and alloys. In aerospace, HSS tools are utilized for machining superalloys and titanium components, essential for aircraft performance and durability. With these industries growing globally, particularly in regions like North America and Asia-Pacific, the demand for precision cutting tools continues to expand, making HSS a vital component in advanced manufacturing processes.

Increased Use of HSS Tools in Metalworking

High-speed steel (HSS) cutting tools have become a staple in metalworking due to their exceptional durability and heat resistance. Metalworking industries, including fabrication and machining, rely on HSS tools for tasks such as drilling, milling, and turning. The ability of HSS tools to maintain their sharpness and resist wear in high-temperature conditions makes them an optimal choice for continuous and high-speed operations. They provide cost-effective solutions by extending tool life and reducing the need for frequent replacements, especially in applications requiring cutting through harder metals. Industries such as automotive, aerospace, and heavy machinery manufacturing depend on these tools for shaping and refining components with precision. As the demand for complex, custom parts increases in these sectors, the utilization of HSS cutting tools remains essential for efficient and high-quality production. The adaptability of HSS to various coatings further enhances its performance, contributing to its continued widespread use.

Manufacturing Growth in Emerging Markets

The rapid growth of manufacturing in emerging markets, especially in regions like Asia-Pacific, is significantly contributing to the demand for high-speed steel (HSS) cutting tools. Countries such as China and India are witnessing increased industrial activities due to favorable government policies, rising foreign investments, and expanding infrastructure projects. As manufacturing hubs grow, there is a heightened need for efficient and durable cutting tools to meet production demands. The versatility of HSS tools, combined with their ability to handle a wide range of materials and applications, makes them a preferred choice in these developing economies. Additionally, as industries like automotive, electronics, and consumer goods expand in these regions, the requirement for precise machining processes is increasing, further boosting the demand for HSS cutting tools. The affordable pricing of HSS tools compared to carbide counterparts is another factor that appeals to cost-sensitive manufacturing sectors in these rapidly growing markets.

Request for a sample copy of this report: https://www.imarcgroup.com/high-speed-steel-cutting-tools-market/requestsample

High Speed Steel Cutting Tools Market Report Segmentation:

Breakup By Type:

- Milling

- Drilling

- Tapping

- Reaming and Counterboring

- Broaching

- Others

By the type, the market is segmented into milling, drilling, tapping, reaming and counterboring, broaching, and others.

Breakup By Technology:

- Conventional

- CNC (Computerized Numerical Control)

Based on the technology, the market is divided into conventional and CNC (computerized numerical control).

Breakup By End Use Industry:

- Automotive

- Aerospace and Defense

- Oil and Gas

- Energy and Power

- Marine

- Others

On the basis of the end use industry, the market is categorized into automotive, aerospace and defense, oil and gas, energy and power, marine, and others.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Based on the region, the market is classified into North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa.

Top High Speed Steel Cutting Tools Market Leaders:

The high speed steel cutting tools market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

- Addison Co. Ltd. (Amalgamations Group)

- Big Kaiser Precision Tooling Inc. (Heinz Kaiser AG)

- Black Decker Corporation (Stanley Black Decker Inc.)

- Erasteel Inc. (Eramet-SLN)

- Kennametal Inc.

- Nachi America Inc. (Nachi-Fujikoshi Corp.)

- Niagara Cutter LLC (Seco Tools AB), OSG Korea Corporation

- Sandvik AB and Sumitomo Electric Industries

Browse full report with TOC List of Figures: https://www.imarcgroup.com/request?type=reportid=3727flag=C

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145